An oil burner needs the same attention as your car to avoid risks and perform at its best.

Regular inspection, component maintenance and servicing are essential to ensure your burner runs reliably and efficiently.

Just 1-2mm of soot build-up increases oil usage by ~4%.

Danfoss Oil Burner Service Recommendations

- Clean burner and boiler chamber

- Change oil nozzles annually

- Change cartridge and ring filters annually

- Check for clogged, blocked or defective pumps

Danfoss Oil Nozzles

The oil nozzle is an essential part of an oil-fired system and plays a vital role in combustion. That’s why Danfoss manufacture precision oil nozzles paying attention to every smallest detail.

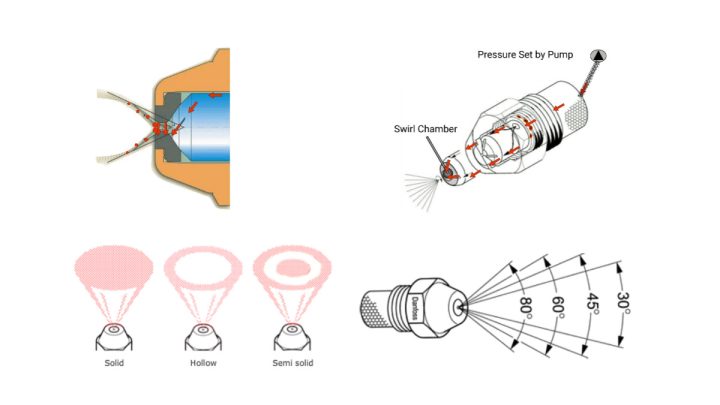

The oil nozzle produces tiny oil droplets that measure between 5 and 100 micrometres using the pressure the pump creates.

These atomised droplets created and rotated in the swirl chamber are forced out in the required spray pattern allowing for a controlled flame when the fuel is ignited with a spark.

Danfoss assembles its nozzles using brass for the housing, sintered bronze balls for the filter, and silver or stainless steel for the internal cone and orifice disc.

Danfoss oil nozzles are:

- Electronically tested to comply with narrow capacity and spray pattern tolerances

- Manufactured in both brass and steel nozzle variants

- Provide unsurpassed compliance and reliability

- EN nozzles (1992)

- OFTEC standard (1995)

- CSA standard

- Danfoss is also ISO 9001 certified.

Using the correct nozzles ensures efficient burner operation and minimises oil usage, pollution and risk of breakdown.

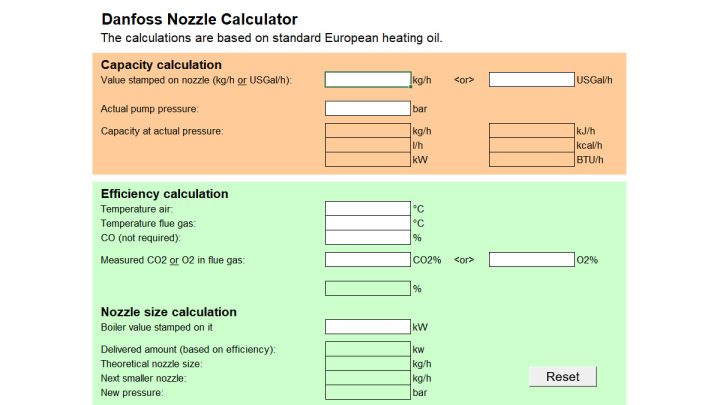

Danfoss has created the oil nozzle calculator spreadsheet to calculate the capacity, efficiency and size of Danfoss oil nozzles required for your burner.

https://files.danfoss.com/download/Heating/Software/Burner/NozzleCalc_UK06.xls

Need help finding the correct nozzles for your burner? Ask ABGO on 01902 790 900 and view Danfoss Oil Burner Nozzles online now.